Centrifugal Galvanizing

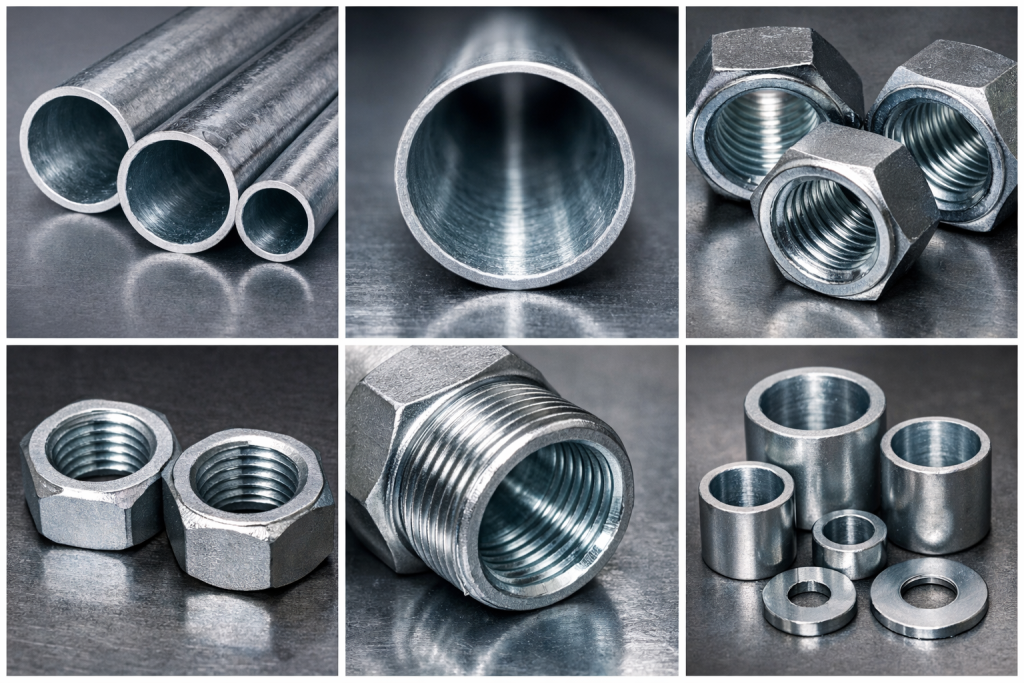

Centrifugal galvanizing is a specialized corrosion‑protection process where molten zinc is applied to the internal surfaces of steel components using centrifugal force. Unlike traditional galvanizing, this method ensures uniform zinc coating inside pipes, tubes, fasteners, threaded components, and cylindrical parts — even in areas difficult to reach. The process is ideal for high‑precision industrial components that demand consistent protection against corrosion and wear.

How Centrifugal Galvanizing Works

Preparation & Cleaning

All components undergo thorough cleaning to remove oil, rust, mill scale, and other impurities.

Fluxing

After cleaning, parts are dipped in flux to prevent oxidation and improve wettability with molten zinc

Centrifugal Coating

Centrifugal force pushes the zinc into every internal contour, forming a smooth, continuous protective layer.

Cooling & Inspection

It is then inspected for thickness, uniformity, and adhesion to ensure compliance with quality standards.

Key Features & Benefits

Superior Internal Corrosion Protection

- Coats interior surfaces uniformly.

- Eliminates unprotected areas common in conventional methods.

Enhanced Durability

- Creates a dense, metallurgically bonded zinc layer.

- Extends service life even in harsh environments.

Precision & Consistency

- Centrifugal action ensures controlled coating thickness.

- Ideal for critical industrial components and high‑performance applications.

Minimal Surface Imperfections

- Produces a smooth finish with reduced buildup or drip marks.

- Greatly improves aesthetics and functional performance.

Infrastructure & Capacity

75,000

Total Area (Sq.ft)

54,000

Built up area (Sq.ft)

3,500MT

Monthly Capacity

50 MT

Weight Bridge Capacity

1000 L/hour

ETP Capacity

250 KVa

Diesel Generator

Creanes & handling Equipment

No. of Overhead creanes 12, forklifts, Hadya